Imagine holding a complex object in your hand that initially existed only as an idea on a computer screen. How does this digital blueprint transform into physical reality? Often, the answer lies in a powerful technology: CNC machining. CNC machining is a cornerstone of modern manufacturing, making it possible to precisely fabricate parts from various materials directly based on computer designs. This technology has permeated numerous industries. Let’s embark on a journey to understand CNC machining from the ground up. We will explore what CNC means, how it works, the machines involved, machinable materials, advantages and disadvantages, and its application areas.

CNC? What Exactly Is It?

What is CNC?

CNC stands for “Computer Numerical Control,” which means using a computer to control machines like milling machines, lathes, or even 3D printers. Any machine operated via computer commands can be called CNC equipment.

How Does CNC Machining Work?

Simply put, CNC machining is a “subtractive” process, meaning it removes excess material from a block of raw material (like metal or plastic) to create the desired shape. The entire process is automated; the machine follows pre-written programs without needing manual intervention during cutting.

The key to this process lies in: first designing a model using CAD (Computer-Aided Design) software, then translating this design into a series of instructions (like G-code). The CNC machine’s controller reads these instructions and then directs the movement of the cutting tools and the rotation of the workpiece, ultimately machining the part with high precision.

To summarize:

- CNC is a technology for automatically controlling machines.

- It manufactures parts by “removing material.”

- Its main characteristics are “automation” and “high precision.”

This clearly distinguishes it from “additive” processes like 3D printing. Although computers can also control 3D printers, when we talk about “CNC machining,” we are specifically referring to the process of cutting material away.

A Brief History

CNC isn’t a brand-new technology. Its concept originated in the United States in the 1940s, initially driven by the massive demand for precision machining in the aerospace industry (e.g., manufacturing helicopter rotor blades). John T. Parsons and the Massachusetts Institute of Technology (MIT) were key early pioneers. With the advent of computers and microprocessors, the initial Numerical Control (NC) evolved into the Computer Numerical Control (CNC) we know today. This technology experienced a long journey from concept proposal to technological breakthroughs, widespread application, and globalization, continuously driving progress in manufacturing.

Behind the Scenes of CNC Machining: The Workflow Explained

CNC machining transforms a digital idea into a physical part through a standardized workflow. This interconnected process forms a “digital thread” from design to manufacturing, translating abstract design information through layers of software and hardware interpretation, ultimately materializing it into a precise physical form.

Step 1: From Idea to Drawing (CAD – Computer-Aided Design)

Everything begins with the design. Engineers or designers use Computer-Aided Design (CAD) software to create a digital model of the part, which can be a 2D drawing or, more commonly, a 3D model. This model precisely defines the part’s geometry, dimensions, tolerances, and all features. Common CAD software includes AutoCAD, SolidWorks, Fusion 360, CATIA, and Siemens NX. After design completion, it’s typically exported in standard file formats like STEP or IGES for subsequent software to read.

At this stage, considering Design for Manufacturing (DFM) is crucial. DFM means designing with consideration for whether the part can be efficiently and economically produced using processes like CNC, avoiding structures that are difficult to machine or overly costly.

Step 2: Translating Design Language into Machine Language (CAM – Computer-Aided Manufacturing & G-code/M-code)

With the CAD model ready, the next step is importing it into Computer-Aided Manufacturing (CAM) software. CAM software acts as both a “translator” and a “strategist”:

- Analyze Model: CAM software reads and analyzes the geometric information of the CAD model.

- Plan Strategy: The user (typically a CNC programmer or machinist) defines the machining strategy within the CAM software, including selecting appropriate cutting tools, setting spindle speed, feed rate (tool movement speed), depth of cut per pass, and other parameters.

- Generate Toolpaths: The core function of CAM software is to calculate and generate Toolpaths, the precise movement trajectories the tool must follow during machining to remove material.

- Simulation & Verification: Most CAM software offers simulation capabilities to visualize the machining process on the computer, checking for correct toolpaths, potential collisions, etc.

Common CAM software includes Mastercam, Autodesk Fusion 360 (which integrates CAD and CAM), PowerMill, and Siemens NX CAM.

G-code and M-code Generation:

Ultimately, CAM software needs to convert the planned toolpaths and machining instructions into a language that the CNC machine tool can “understand.” This language is G-code and M-code.

- G-code (Geometric Code): Primarily controls the machine’s movement. For example, G00 commands rapid positioning (no cutting), G01 commands linear interpolation (cutting along a straight line), and G02/G03 command circular interpolation (clockwise and counter-clockwise arcs). G-code also defines target coordinates (e.g., X, Y, Z positions) and speed (feed rate F).

- M-code (Miscellaneous Function Code): Controls the machine’s non-movement functions. For example, M03 starts the spindle clockwise, M04 counter-clockwise, M05 stops the spindle; other commands control coolant activation, tool changes, etc.

These codes are typically organized into “blocks,” with each block containing one or more instructions executed sequentially. While simple G-code can be manually written or modified using a text editor (like Notepad++), for complex parts, it’s almost entirely generated automatically by CAM software.

The Crucial Role of Post-Processors and Firmware:

Two key concepts need understanding here: Post-processor and Firmware. Different CNC machines (e.g., those with Fanuc, Siemens, Haas controllers, or based on open-source solutions like GRBL, Marlin) essentially speak different “dialects.” The Firmware running inside them determines the specific G-code format and the set of commands they can understand.

The generic toolpath information generated by CAM software needs to be “translated” by a Post-processor. A post-processor is a file or program configured for a specific machine/controller combination. It converts the CAM output into the precise G-code and M-code that the specific machine can accurately recognize and execute. Selecting or configuring the correct post-processor is vital for successful machining; it’s the critical bridge connecting the CAM software to the physical machine tool. One could say CAM performs the first translation from “design intent” to “generic motion commands,” while the post-processor performs the second, equally crucial translation from “generic motion commands” to “specific machine language.”

Step 3: Meticulous Preparation, Precise Execution (Machine Setup)

Before automated machining begins, a series of careful manual setup tasks are essential. Although CNC machining is highly automated during cutting, the human operations in the preparation phase are critical to the final result. Any error can lead to machining failure or unmet precision requirements.

- Program Loading: Transfer the generated G-code file to the CNC machine controller’s memory via network, USB, or other methods.

- Workpiece Clamping: Place the raw material (Workpiece) onto the machine’s table (milling machine) or chuck (lathe) and secure it firmly using Fixtures, a Vise, or other methods to prevent displacement during machining.

- Tool Installation: Based on the CAM machining plan, install the required cutting tools (e.g., end mills, drills, turning tools) into the machine’s spindle or tool magazine/turret. For machines equipped with an Automatic Tool Changer (ATC), all necessary tools must be pre-loaded into the magazine.

- Coordinate System & Tool Setting: Set the Work Offset, which defines the program zero point’s specific location on the workpiece (e.g., a corner or center), and communicate this position to the machine controller. Simultaneously, accurately measure the length and radius of each tool and input this data into the controller for Tool Length Compensation and Tool Radius Compensation. This allows the controller to accurately calculate the actual position of the tool tip or center, ensuring machining according to the programmed dimensions.

Step 4: Automated Machining

Once everything is ready, the operator starts the program.

- Instruction Execution: The CNC controller reads the G-code line by line.

- Signal Transmission: The controller converts instructions into electrical signals sent to the servo drive system.

- Drive Movement: Servo drives control servo motors (or stepper motors) to precisely move the machine’s various axes (X, Y, Z, and rotary axes A, B, C, etc.), while controlling the spindle to rotate at the specified speed.

- Material Removal: Guided by the program, the high-speed rotating tool cuts the workpiece along the predetermined path, progressively removing material to form the designed shape.

- Feedback Control (Closed-Loop System): Many high-precision CNC machines use closed-loop control. They are equipped with position detection devices (like linear scales or encoders), which constantly monitor the actual position of the machine axes and feed this information back to the controller. The controller compares the actual position with the commanded position and makes corrections if there’s a discrepancy, achieving higher positioning accuracy. Simpler systems might be open-loop or semi-closed-loop, offering relatively lower accuracy.

- Trial Run: Before machining expensive materials, a “dry run” (without contacting the workpiece) or a test cut using inexpensive material (like wax) is often performed to verify the program’s correctness and the setup’s accuracy.

This complete process from CAD to CAM to machine execution embodies the concept of the “digital thread” in modern manufacturing, accurately translating virtual designs into physical reality.

Common Machine Types

CNC technology isn’t applied to a single type of machine but drives a vast “family of machine tools,” each member having unique construction and areas of expertise. The choice of CNC machine primarily depends on the properties of the material to be processed and the geometry and precision requirements of the final part. There is no “universal” CNC machine; they are specialized tools optimized for specific tasks.

Machine tools are often classified by the number of motion axes they can simultaneously control, such as 3-axis, 4-axis, 5-axis, etc. More axes generally mean the machine can handle more complex geometries and complete multiple faces of a part in fewer setups, thus improving efficiency and accuracy.

Here are some of the most common types of CNC machines:

CNC Milling Machines

- Function: One of the most widely used CNC machines. It uses high-speed rotating multi-point cutting tools (like end mills, face mills) to remove material from the workpiece. Typically, the workpiece is fixed on the table, while the tool moves in the X, Y, and Z linear directions (some designs have table movement). Milling machines are very versatile and can produce flat surfaces, steps, grooves, holes, and complex 3D surfaces and contours.

- Axes: The most common is the 3-axis mill, where the tool moves left/right (X), front/back (Y), and up/down (Z). A 4-axis mill adds a rotational axis (usually A or B) to the 3 axes, facilitating machining on the sides of parts or cylindrical features. A 5-axis mill has three linear axes and two rotational axes, allowing the tool to approach the workpiece from more complex angles. This enables machining of very complex parts (like turbine blades, intricate mold cavities) in a single setup, significantly reducing errors from repeated positioning and improving machining accuracy and surface finish.

- Uses: Widely used in mold making, aerospace parts machining, automotive component production, medical device manufacturing, precision instrument making, and the prototyping and mass production of various complex parts.

- Key Point: Highly flexible, capable of machining complex shapes, especially 5-axis machines.

CNC Lathes / Turning Centers

- Function: Unlike milling machines, lathes cause the workpiece itself to rotate at high speed in a chuck, while the cutting tool moves linearly along the workpiece’s axial (Z-axis) and radial (X-axis) directions to cut the desired rotational shape. Lathes are primarily used for manufacturing parts with axisymmetric features, such as cylinders, cones, spheres, and threads. They can perform operations like turning outer diameters, facing ends, drilling, boring (enlarging holes), threading, and grooving.

- Types: The most basic is a 2-axis lathe, controlling X and Z motion. Modern Turning Centers are more powerful and may feature:

- Live Tooling: Tools in the turret can also rotate, allowing milling, drilling, and other non-rotational features to be machined on the rotating workpiece.

- C-axis: The main spindle can be precisely positioned angularly, enabling more complex machining in conjunction with live tooling.

- Y-axis: The tool can move perpendicular to the XZ plane.

- Sub-spindle: Allows transferring the part from the main spindle to a secondary spindle to machine the other end, achieving “Done-in-one” completion. These advanced features enable turning centers to efficiently produce complex rotational parts.

- Uses: Manufacturing various shaft and disk-type parts, such as engine crankshafts, camshafts, screws, fittings, valve parts, flanges, etc.

- Key Point: Efficient for machining rotational parts; modern turning centers are highly capable.

CNC Routers

- Function: CNC routers work similarly to milling machines, using rotating tools for cutting. However, they are typically lighter in structure, have very high spindle speeds (RPM much higher than mills), and relatively lower cutting forces. They often employ a gantry structure, where the tool spindle is mounted on a beam spanning the worktable and moves in X, Y, and Z, while the workpiece usually remains stationary on the table.

- Materials: Due to their structural rigidity and spindle characteristics, routers are primarily designed for machining softer materials, such as various woods (solid wood, plywood, MDF), plastics (acrylic, PVC, ABS), foam materials, composites, and softer metals like aluminum.

- Uses: Widely applied in the woodworking industry (furniture, cabinets, carving), signage production (cutting letters, logos), plastics processing, model making, musical instrument manufacturing, and cutting large-format sheet goods. Available from desktop hobbyist machines to large industrial equipment.

- Main Difference vs. Milling Machine: Compared to mills, routers generally have lower rigidity, higher spindle RPM, lower torque, and are better suited for soft materials and large sheets. Mills have high rigidity, relatively lower spindle RPM, higher torque, and are designed for high-precision, efficient cutting of metals and other hard materials.

- Key Point: High-speed machining of soft materials, especially adept at wood, plastic, and large-format cutting.

CNC Plasma Cutters

- Function: Uses a plasma arc for cutting. Plasma is a high-temperature (up to tens of thousands of degrees Celsius) ionized gas, ejected at high speed through a nozzle, sufficient to melt and blow away metal material, forming a cut. The CNC system controls the movement path of the plasma torch.

- Materials: Can only cut conductive materials, primarily various metals like carbon steel, stainless steel, aluminum, copper, brass, etc.

- Uses: Widely used for cutting metal plates, structural steel processing, machinery manufacturing, automotive repair, shipbuilding, pressure vessel fabrication, scrap recycling, etc. Characterized by fast cutting speeds, especially efficient for medium to thick metal plates, and relatively low equipment cost.

- Key Point: High-speed cutting of conductive metals, cost-effective, especially suitable for medium-thick plates.

Other Important Members (Brief Introduction)

Besides the four above, the CNC family includes other important members employing different physical principles for material removal:

- CNC Laser Cutters: Use a focused high-energy laser beam to melt, burn, or vaporize material for cutting or engraving. Very high precision, capable of cutting intricate patterns. Suitable for metals (especially thin sheets), plastics, wood, leather, fabric, etc. (depending on laser type, e.g., CO2 or Fiber). Often faster than plasma for thin sheets, but limited cutting thickness capability and challenges with highly reflective materials (like copper, brass). Creates a Heat-Affected Zone (HAZ).

- CNC Waterjet Cutters: Utilize an extremely high-pressure stream of water (often mixed with abrasives like garnet) to erode and cut material like a “knife.” This is a “cold cutting” process, generating almost no heat, thus no HAZ. Ideal for heat-sensitive materials (like certain plastics, composites) or applications requiring preservation of original material properties (like aerospace). Can cut almost any material, including very hard (titanium, stone, ceramics) and very soft (rubber, foam), and can cut very thick materials (up to several tens of centimeters). High precision, but cutting speed is generally slower than laser or plasma, and equipment/running costs (mainly abrasive consumption) can be higher.

- CNC Electrical Discharge Machines (EDM): Use periodic pulsed electrical discharges between a tool electrode and the workpiece to erode conductive material via high temperatures. Excellent for machining ultra-hard materials (like hardened steel, carbide) that are difficult to cut conventionally, and for creating parts with complex shapes, deep narrow slots, small holes, sharp internal corners. Commonly used in precision mold making (especially injection and stamping molds) and special parts manufacturing. No macroscopic cutting forces, avoiding mechanical stress on the workpiece. Disadvantages: only works on conductive materials, relatively slow machining speed. Two main types: Sinker EDM (using a shaped electrode) and Wire EDM (using a thin wire as the electrode).

- CNC Grinding Machines: Use a high-speed rotating abrasive wheel to finish the surface of a workpiece, achieving extremely high dimensional/shape accuracy and very low surface roughness. Often the final step in part processing to remove small amounts of material, correct errors, and obtain a mirror-like finish.

- CNC Drilling Machines: Specialized for high-efficiency, high-precision drilling operations.

| Machine Type | Main Function | Typical Materials | Common Uses | Main Advantages | Main Limitations |

| CNC Milling Machine | Machining planes, surfaces, complex contours | Metals, Plastics, Composites | Molds, Aerospace parts, Auto components, Prototypes | High precision, High flexibility, Complex shape capability | Higher equipment cost, Requires skilled operators |

| CNC Lathe | Machining rotational parts (cylinders, etc.) | Metals, Plastics | Shafts, Pins, Screws, Flanges, Engine parts | High efficiency for rotational parts, Powerful centers | Primarily limited to rotationally symmetric shapes |

| CNC Router | High-speed cutting, engraving, large sheets | Wood, Plastics, Foam, Soft Metals (Al) | Furniture, Signage, Models, Plastic goods, Wood art | Fast for soft materials, Large work area, Lower cost | Lower rigidity, Not for hard metals, Lower precision than mill |

| CNC Plasma Cutter | High-speed cutting of conductive metal plates | Conductive Metals (Steel, SS, Al, Cu) | Steel structures, Sheet metal fab, Shipbuilding | Fast for med-thick plates, Cost-effective | Conductive materials only, HAZ, Relatively lower precision |

It’s worth noting the industry trend towards multi-functional, hybrid machines, such as turning centers with milling capabilities (Mill-Turn machines). These machines aim to complete all or most operations on a part in a single setup, reducing turnaround time, improving machining accuracy, and boosting production efficiency, especially for complex parts. Of course, this comes with higher equipment costs and more complex operational requirements.

Furthermore, for cutting applications (plasma, laser, waterjet), there are clear technological trade-offs. Plasma cutting is fast and low-cost for medium-thick conductive metals but has lower precision and a HAZ. Laser cutting is fast and precise for thin sheets, works on a wider range of materials, but has thickness limitations, difficulty with reflective materials, and a HAZ. Waterjet cutting handles almost any material, offers high precision, no HAZ, and can cut very thick materials, but is typically the slowest, and running costs can be higher. Therefore, selecting the right cutting technology requires a comprehensive assessment based on the specific material, thickness, precision needs, budget, and required production efficiency.

What Materials Can CNC Machine?

A major advantage of CNC machining technology is its wide material compatibility. Theoretically, any material that can be removed by a cutting tool could potentially be processed via CNC. However, it’s important to emphasize that while the CNC technology itself is broadly applicable, specific CNC machines and the chosen tools are usually optimized for certain categories of materials. For instance, a CNC router used for wood will differ significantly in structural rigidity, spindle power, speed range, and tool types from a CNC mill used for machining titanium alloys.

Here are the major categories of materials commonly processed by CNC:

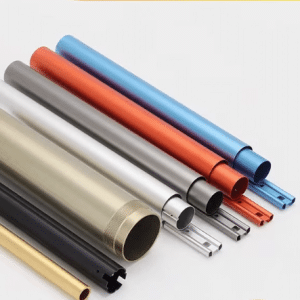

Metals

Metals are among the most frequently handled materials in CNC machining, with extremely broad applications.

- Aluminum Alloys: Popular due to their light weight, moderate strength, good machinability, corrosion resistance, and relatively low cost. Commonly used in aerospace, automotive, electronics enclosures, consumer products, etc.

- Steel:

- Stainless Steel: Excellent corrosion resistance, strength, and good appearance. Widely used in medical devices, food processing equipment, chemical equipment, architectural decoration, etc.

- Carbon Steel: Includes low, medium, and high carbon steel. High strength, relatively low cost, widely used for mechanical parts, structural components, etc.

- Tool Steel: High hardness, good wear resistance, primarily used for making molds, cutting tools, etc.

- Titanium Alloys: Possess an extremely high strength-to-weight ratio, outstanding corrosion resistance (even better than stainless steel), and good biocompatibility. Ideal materials for aerospace (aircraft structures, engine parts) and medical implants (artificial joints, dental implants). However, titanium alloys are difficult to machine, requiring high machine rigidity, specific tools, and cutting parameters.

- Copper and Copper Alloys:

- Brass: Easy to machine, corrosion-resistant, often used for valves, fittings, musical instruments, decorative items.

- Copper: Excellent electrical and thermal conductivity, primarily used for electronic components, heat sinks, etc.

- Bronze: Wear-resistant, corrosion-resistant, often used for bearings, gears, sculptures.

- Other Metals: Magnesium alloys (ultra-light), superalloys (like Inconel, for extreme environments), zinc alloys, etc., can also be CNC machined.

Non-Metals (Plastics)

Plastics hold an important place in CNC machining due to their light weight, insulation properties, corrosion resistance, ease of forming, and cost-effectiveness.

- General Engineering Plastics:

- ABS: Good strength, high toughness, easy to machine. Often used for housings, toys, automotive interior parts.

- Nylon (PA): High strength, good wear resistance, self-lubricating. Used for gears, bushings, sliders.

- Polycarbonate (PC): High strength, high transparency, impact resistant. Used for protective covers, lenses, electronic device housings.

- POM (Delrin): Good rigidity, dimensional stability, low friction coefficient. Used for precision parts, gears, snap-fits.

- Acrylic (PMMA): High transparency, good weather resistance, often replaces glass. Used for displays, light covers, signs.

- High-Performance Engineering Plastics:

- PEEK: High-temperature resistance, chemical resistance, high strength. Used in demanding fields like aerospace, medical, semiconductors.

- PTFE (Teflon): Extremely low friction coefficient, excellent chemical resistance, high/low temperature resistance. Used for seals, insulators, coatings.

- Other Common Plastics: PVC (rigid, corrosion-resistant), Polyethylene (PE), Polypropylene (PP), etc.

Wood

CNC routers excel in wood processing.

- Solid Wood:

- Hardwoods: Oak, maple, walnut, cherry, etc. High density, beautiful grain, durable. Used for high-end furniture, flooring, carvings.

- Softwoods: Pine, cedar, fir, etc. Lower density, easy to machine, lower cost. Used for general furniture, construction, prototypes.

- Engineered Woods:

- Plywood: Made from multiple layers of wood veneer glued together. Good strength, dimensionally stable.

- Medium-Density Fiberboard (MDF): Wood fibers compressed with resin. Smooth, uniform surface, easy to paint. Used for cabinets, display panels, decorative trim.

Emerging Forces (Special Materials)

Besides traditional materials, CNC technology is increasingly applied to some special materials.

- Composites: Made from two or more materials with different properties, like Carbon Fiber Reinforced Polymer (CFRP), Glass Fiber Reinforced Polymer (GFRP). Lightweight and high-strength, widely used in aerospace, automotive, sports equipment. Machining composites usually requires special tools and processes.

- Foam: Polystyrene foam (EPS), Polyurethane foam (PU), PMI foam, etc. Lightweight, easy to machine. Often used for making models, mold prototypes, packaging, insulation/soundproofing materials.

- Ceramics: Extremely hard, wear-resistant, high-temperature resistant, but brittle. Machining ceramics typically requires diamond tooling for grinding, or non-contact methods like laser or EDM (for conductive ceramics). Waterjet cutting is also an option.

- Others: Glass, stone, etc., can also be processed by CNC, often using waterjet or specialized grinding/engraving processes.

The choice of material not only determines the final product’s performance but also directly impacts the CNC machining process itself. Different material properties like hardness, toughness, thermal conductivity, melting point, etc., dictate the type of machine, tooling, and appropriate process parameters (cutting speed, feed rate, cooling method). For example, machining hard materials requires a more rigid machine and more wear-resistant tools, possibly needing lower cutting speeds to control heat and tool wear; whereas soft plastics can be machined at higher speeds, but care must be taken to prevent melting and tool clogging. Material cost itself is also a significant part of the total project cost. Therefore, a deep understanding of material properties and their impact on the machining process is crucial for successful CNC implementation.

The Superpowers of CNC Machining: Why Is It So Popular?

Compared to traditional, manually operated machining methods, CNC machining plays an increasingly important role in modern manufacturing due to its unique advantages. The core driver of these benefits is its computer-controlled automation, which overcomes many limitations inherent in manual operations.

Unmatched Precision and Repeatability

- High Precision: This is one of the most significant advantages of CNC machining. Computer control enables precise movements unattainable by human hands, allowing CNC machines to produce parts with extremely tight dimensions and tolerances. Accuracy can often reach the micrometer (µm) level, e.g., ±0.025 mm (equivalent to one-thousandth of an inch) or even better. This high precision is critical for demanding industries like aerospace and medical devices.

- High Repeatability/Consistency: CNC machines can rigorously execute machining tasks according to program instructions repeatedly, ensuring high consistency among every part produced. This is particularly important for mass production, guaranteeing stable and reliable product quality. Automation significantly reduces human errors caused by operator fatigue, distraction, or skill variations.

Boost in Speed and Efficiency

- High Speed: CNC machines can typically complete machining tasks faster than manual operations. Machines can run continuously without needing breaks like humans.

- High Efficiency: High degree of automation, such as Automatic Tool Changers (ATC) that can swap tools in seconds, drastically reduces non-cutting time. The overall machining process is smoother, production cycles are significantly shortened, thereby increasing overall production efficiency and equipment utilization.

Mastery Over Complex Designs

- Machining Complex Shapes: Computer control enables CNC machines to accurately execute complex toolpaths, manufacturing parts with intricate geometries, freeform surfaces, and fine features. This is often extremely difficult or impossible with traditional manual machining. Multi-axis CNC machines (5-axis and above) are particularly capable of handling complex parts.

The Liberation of Automation

- Reduced Labor Dependency: Once the program is debugged and the machine is set up, the CNC machining process can run highly automatically, reducing the need for continuous manual operator intervention. A skilled operator can sometimes monitor multiple CNC machines simultaneously.

- Improved Safety: Operators are usually kept at a distance from high-speed rotating tools and the cutting zone, often monitoring from behind safety doors, reducing the risk of industrial accidents.

- Reduced Labor Intensity: Automation lessens the physical and mental strain on operators, avoiding fatigue from prolonged repetitive manual tasks.

Other Advantages

- Flexibility: Switching production to different parts is relatively easy, requiring only loading a different program and changing corresponding tools and fixtures. This adapts well to low-volume, high-variety production needs.

- Reduced Waste: High-precision machining minimizes errors and scrap rates, thus minimizing material waste.

- Simplified Assembly: Due to precise and consistent part dimensions, subsequent assembly work becomes smoother and more efficient.

It’s worth noting that although CNC is often associated with mass production, its high precision, flexibility, and rapid response also make it highly suitable for one-off customization and rapid prototyping. For scenarios requiring quick design validation, manufacturing functional prototypes, or producing personalized products, CNC offers irreplaceable advantages.

CNC Machining vs. Traditional Manual Machining Comparison

The table below summarizes key differences between CNC machining and traditional manual machining:

| Feature/Aspect | CNC Machining | Traditional Manual Machining |

| Accuracy | Very High, Micron-level, Computer Ctrl | Depends on Operator Skill, Relatively Lower |

| Repeatability | Excellent, High Batch Consistency | Lower, Affected by Human Factors |

| Speed/Efficiency | Fast, Highly Automated, Short Cycles | Slow, Requires Continuous Manual Operation |

| Complex Shapes | High Capability (esp. Multi-axis) | Limited Capability, Difficult & Time-Consuming |

| Automation Level | High | Low or None |

| Operator Skill Focus | Programming, Setup, Process, Monitor | Manual Skill, Experience, Reading Prints, Measuring |

| Material Waste | Lower (due to high accuracy) | Potentially Higher (due to errors) |

| Safety | Relatively Higher (Operator isolated) | Relatively Higher Risk (Operator close proximity) |

The Application Stage for CNC: Across All Industries

Leveraging its high precision, efficiency, repeatability, and ability to process complex shapes and diverse materials, CNC machining technology has deeply integrated into nearly every aspect of modern industry, becoming an indispensable key manufacturing method for many sectors. Its widespread application demonstrates the core value of this technology: accurately and reliably transforming digital designs into high-quality physical components, meeting demands ranging from cutting-edge technology to everyday consumer goods.

Here are specific application examples of CNC machining technology in major industries:

- Aerospace: One of the earliest fields for CNC application and still one of its most important stages. Aerospace products demand extreme precision, reliability, and lightweighting. CNC machining is used to manufacture (the first CNC machine was used to develop aerospace parts):

- Aircraft engine components (e.g., turbine blades, compressor disks)

- Aircraft structural parts (e.g., fuselage frames, wing spars, connectors)

- Landing gear system components

- Complex instrument housings and brackets

- Satellite and rocket components

- Precision optical components (via special processes like single-point diamond turning) These parts are often made from difficult-to-machine materials like aluminum alloys, titanium alloys, superalloys, and composites. CNC’s multi-axis capability and high-precision control are key to realizing these complex parts.

- Automotive: Another major application area for CNC machining. Both mass-produced cars and racing vehicles rely on CNC technology. Applications include:

- Engine components (e.g., engine blocks, cylinder heads, crankshafts, camshafts, pistons)

- Transmission gears and housings

- Suspension system parts (e.g., control arms)

- Braking system parts (e.g., calipers, brake discs)

- Mold making for body panels and interior components

- Rapid prototyping for new model development and testing

- Custom modification parts CNC technology ensures the precision and consistency of automotive parts, crucial for enhancing vehicle performance, safety, and fuel economy.

- Medical: The medical industry demands extremely high precision, surface finish, and material compatibility (especially biocompatibility). CNC machining is well-suited for manufacturing:

- Surgical Instruments: E.g., scalpel handles, forceps, bone drills, surgical guides, requiring high precision and good corrosion resistance.

- Implants: E.g., artificial joints (hip, knee), spinal fixation devices, dental implants, bone plates, screws. Often uses biocompatible materials like titanium alloys, stainless steel, PEEK. CNC enables personalized customization based on patient specifics.

- Prosthetics and Orthotics: Manufacturing customized supports and connectors.

- Medical Device Housings and Components: Precision enclosures and internal parts for diagnostic equipment, monitors, etc. CNC’s high precision, complex shape capability, and ability to handle special materials make it play a critical role in the medical field.

- Mold Making: Molds are fundamental to many mass production processes (like injection molding, die casting, stamping). CNC machining is the primary method for manufacturing high-precision, complex cavity molds.

- Injection Molds: For producing plastic products.

- Die Casting Molds: For producing metal castings.

- Stamping Dies: For metal sheet forming.

- Extrusion Dies: For producing profiles. CNC milling (especially high-speed and 5-axis milling) and EDM are widely used in mold making, capable of machining hardened mold steels and achieving complex shapes and fine surface textures.

- Prototyping: In the early stages of product development, prototypes are needed quickly to validate designs, perform functional tests, or present to clients. CNC machining is an important rapid prototyping method with advantages like:

- Speed: CNC can directly machine prototypes from CAD data, faster than traditional tooling.

- Real Materials: Prototypes can be made using the same engineering materials (metal, plastic) as the final product, making test results more reliable.

- High Accuracy: Capable of producing dimensionally accurate functional prototypes. CNC is often used for creating appearance models, structural models, and functional prototypes.

- Broader Application Areas:

- Electronics: Manufacturing metal or plastic housings, heat sinks, connectors, internal structural parts for phones, computers, drones, etc.

- Consumer Goods: Making parts for appliances, sports equipment, toys, tools, etc.

- Energy: Manufacturing precision components for oil drilling equipment, gas turbines, generators, wind power equipment.

- Marine: Manufacturing propellers, engine parts, marine hardware.

- Construction: Manufacturing special structural connectors, facade components, decorative elements.

- Art & Design: Artists and designers use CNC to create complex sculptures, art installations, custom furniture.

- Woodworking & Furniture: Manufacturing custom furniture, cabinets, doors, windows, musical instruments, decorative wood carvings.

- Jewelry: Precision machining of wax models for investment casting, or direct machining of precious metals for jewelry.

As can be seen, CNC machining applications are nearly ubiquitous. Wherever precise shaping of solid materials is required, its presence is almost certain. It is this broad applicability and powerful manufacturing capability that make CNC technology an indispensable force supporting modern industrial development.

Learning Paths and Resources

Mastering CNC technology requires a combination of theoretical knowledge and practical operation. Fortunately, numerous learning resources are now available.

Under the resources section of our Fabrapid, there is a wealth of knowledge about CNC machining.

Conclusion

CNC (Computer Numerical Control) machining is an efficient manufacturing method that uses computers to precisely control machine tools, transforming digital designs into physical entities. Renowned for its high precision, repeatability, and automation, it is widely used in fields like aerospace, automotive, medical, mold making, and prototyping, completely changing traditional machining methods.

Although equipment investment and operational requirements are relatively high, with the proliferation of desktop machines, open-source software, and learning resources, CNC machining is becoming increasingly accessible. Whether you are a maker, designer, or business owner, CNC is a key tool for realizing your creative and manufacturing ambitions.

In Fabrapid , we offer professional online CNC machining services, supporting multiple materials and processes. Welcome to upload your drawings for a quote, helping you easily achieve one-stop manufacturing from design to finished product!