Available Finishes for CNC Machining

Attain the ideal finish with our extensive selection of surface treatments. Whether you need anodizing, plating, or painting, we guarantee your parts will fulfill both aesthetic and functional requirements.

Anodizing

Anodizing is an electrochemical process used to enhance the surface of metals, primarily aluminum, improving its corrosion resistance, wear resistance, and providing a variety of decorative colors.

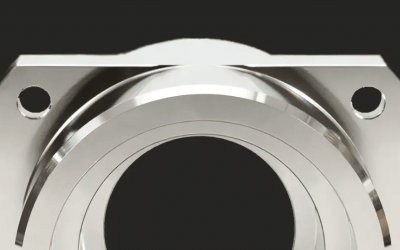

Polishing

Polishing is a finishing process that enhances the surface finish and appearance of materials by removing imperfections and producing a high luster.

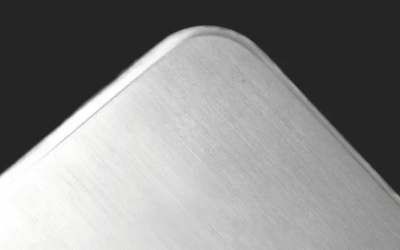

Sand Blasting

Sand blasting is a surface treatment process that involves propelling abrasive particles under high pressure against a surface to clean it or modify its texture.

Tumbling

Tumbling is a finishing technique where parts are placed in a rotating barrel with abrasive media to smooth and polish the surfaces through friction and impact.

Electropolish

Electropolishing is a metal finishing process that uses an electrochemical solution to remove microscopic layers of material from a workpiece, enhancing its surface smoothness and shine.

Heat Treatment

Heat treatment is a controlled process used to alter the physical and sometimes chemical properties of a material, typically metal, to achieve desired mechanical properties such as hardness, ductility, and strength.

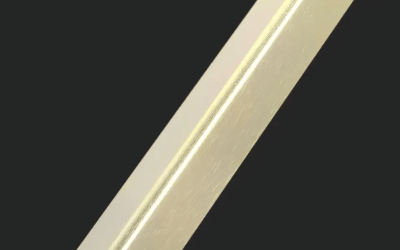

Brushed Finish

A brushed finish is achieved by polishing a metal surface with a fine bristle brush on a belt or wheel that creates a consistent, unidirectional satin-like texture.

Black Oxidize

Black oxidizing is a chemical conversion coating process used on metals, primarily steel, to produce a black surface layer that offers mild corrosion resistance and reduces light reflection.

Powder Coating

Powder coating is a finishing process where a dry powder paint is electrostatically charged and sprayed onto a surface, then cured under heat to form a hard, durable, and colorful protective layer.