Custom 3D Printing Service

Obtain immediate online quotes for 3D printed parts in both plastics and metals. Order high-resolution rapid prototypes and production parts crafted with precision. We offer tolerances as fine as ±0.2 mm. Our services are certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards.

- Free Quote and DfM

- Fast Lead Time

- Pay After Delivery

Our CNC Machining Services

我们的3d打印服务

什么是3d打印

常见问题

行业应用

我们的3D打印服务

fabrapid提供一站式的专业3D打印服务,涵盖当前所有主流增材制造技术,包括 FDM(熔融沉积成型)、SLA(立体光固化)、SLS(选择性激光烧结)以及金属3D打印等。我们的尖端设备和工艺能够满足从快速原型制作到高性能终端零件生产的各种需求,帮助您的设计高效变为现实。

依托庞大的供应商网络和分布式制造基地,fabrapid具备卓越的加工能力和灵活的产能调配。不论订单规模大小,我们都能快速响应并高质量交付。无论您是个人创客、小型初创公司,还是需要批量生产的大型企业,fabrapid的3D打印服务都能够为您提供合适的解决方案,满足各类客户的定制需求。

为什么选择我们

覆盖全系列3D打印工艺: 我们提供FDM、SLA、SLS、DMLS等全系列增材制造技术,可根据项目需求选择最合适的工艺和材料。无论是塑料原型件还是金属功能部件,我们都能胜任,确保您的设计获得理想的强度、精度和表面质量。

强大供应商网络,快速产能: fabrapid拥有广泛的制造合作伙伴网络,可调动全国乃至全球的生产资源。凭借这一网络优势,我们能够大幅缩短生产周期,实现大规模、快速生产和交付,同时保持严格的质量控制,为您的项目争取宝贵时间。

无最小起订量,按需制造: 我们没有最低起订量限制,支持真正的按需生产。哪怕您只需要打印1件样品,也会得到同等重视。这意味着您无需承担大批量订购或开模具的前期成本,就能灵活启动产品原型测试或小批量试制,将风险和投入降到最低。

what is 3d printing?

3d printing is a add

what 3d printing do

什么情况下应该使用3d打印

Our 3D Printing service capabilities

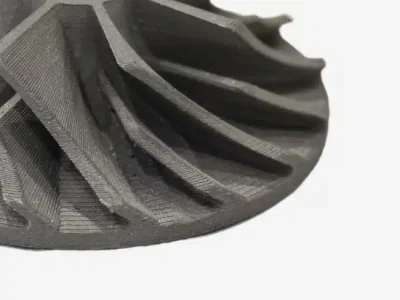

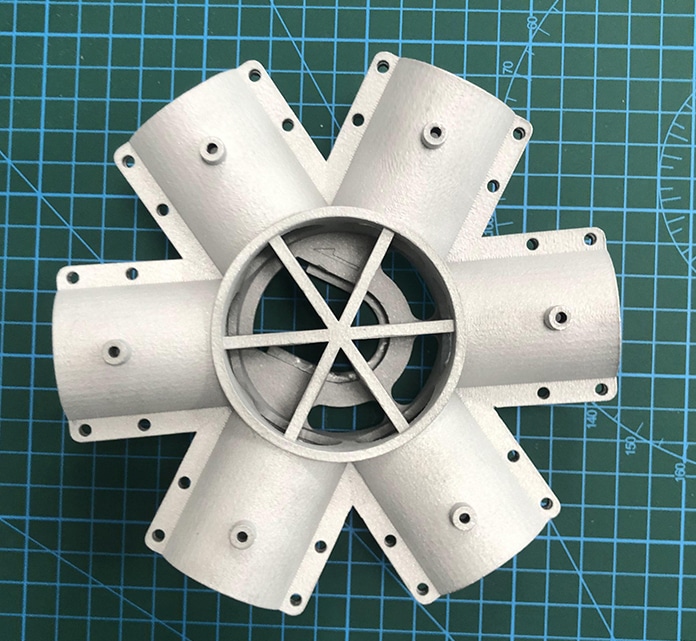

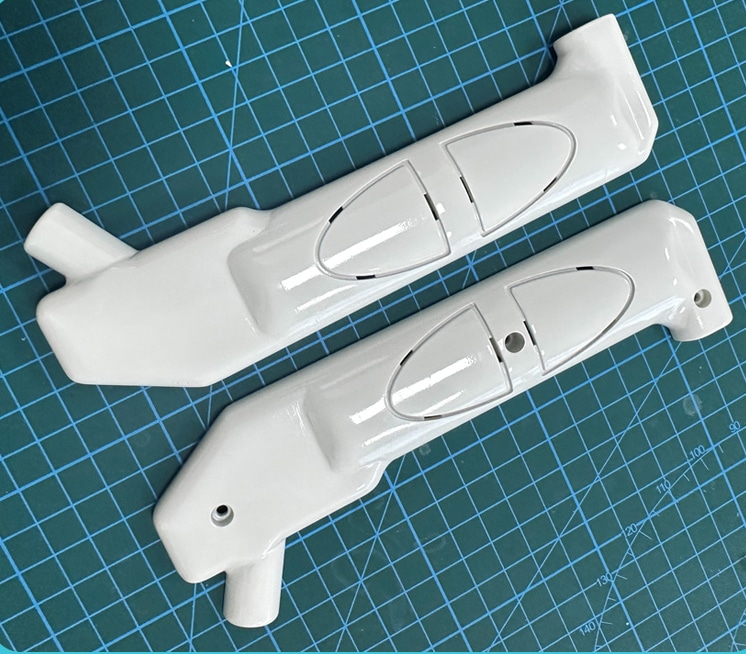

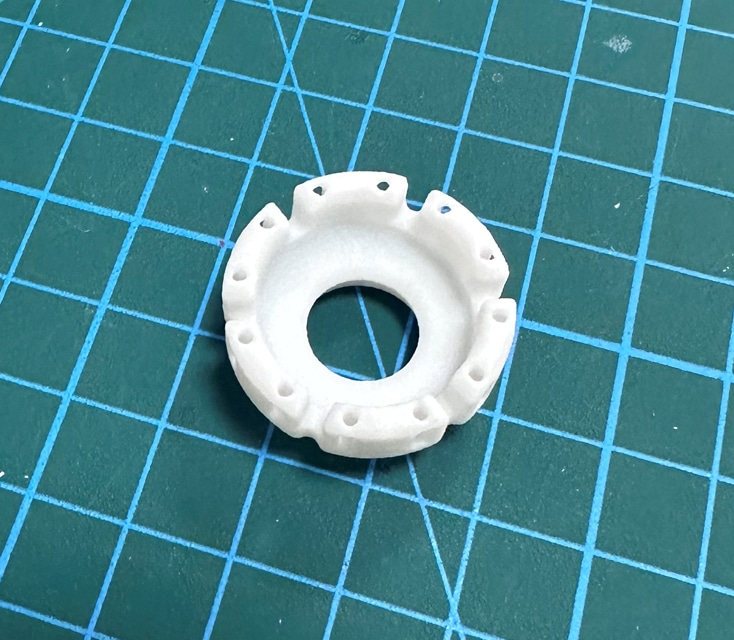

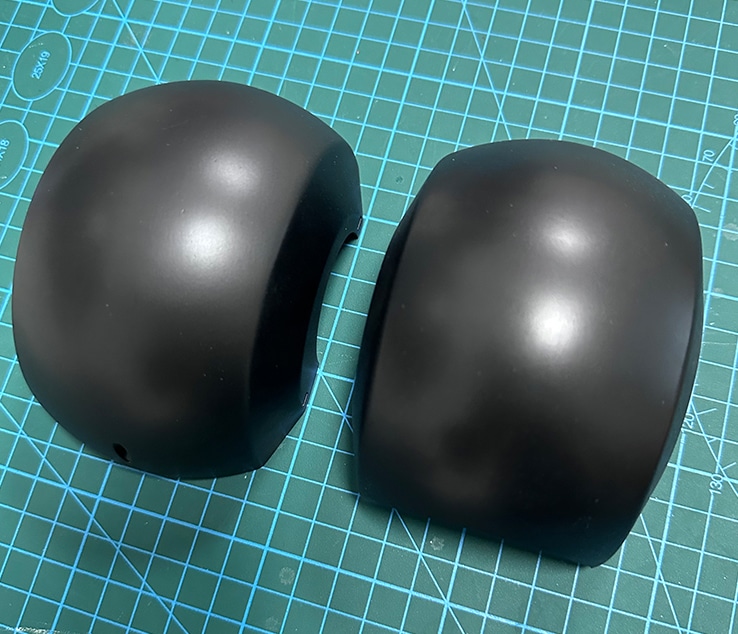

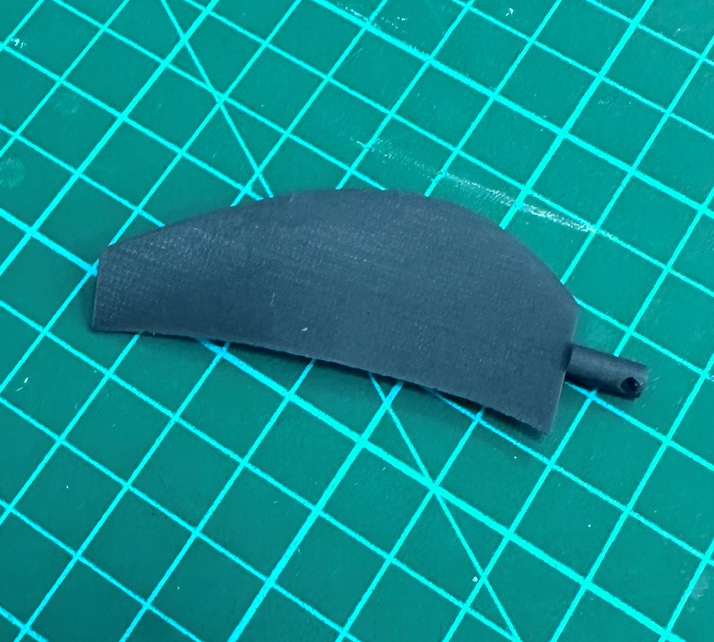

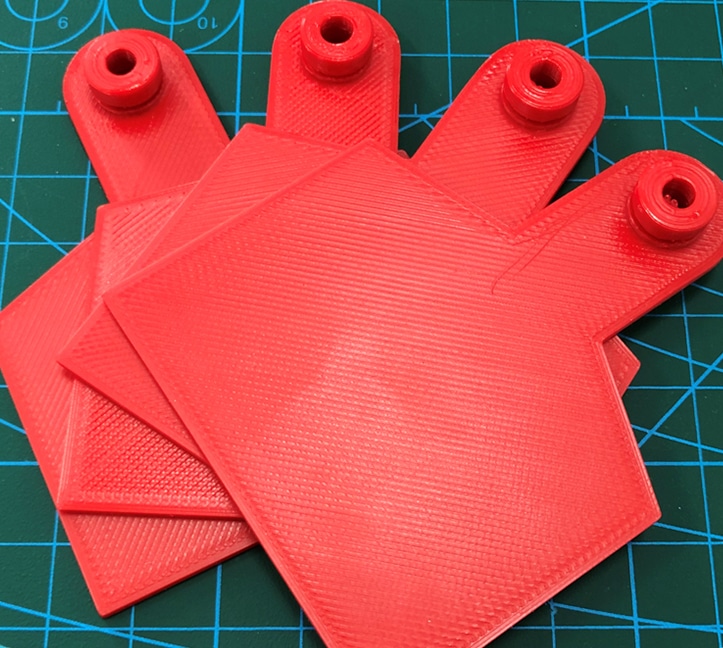

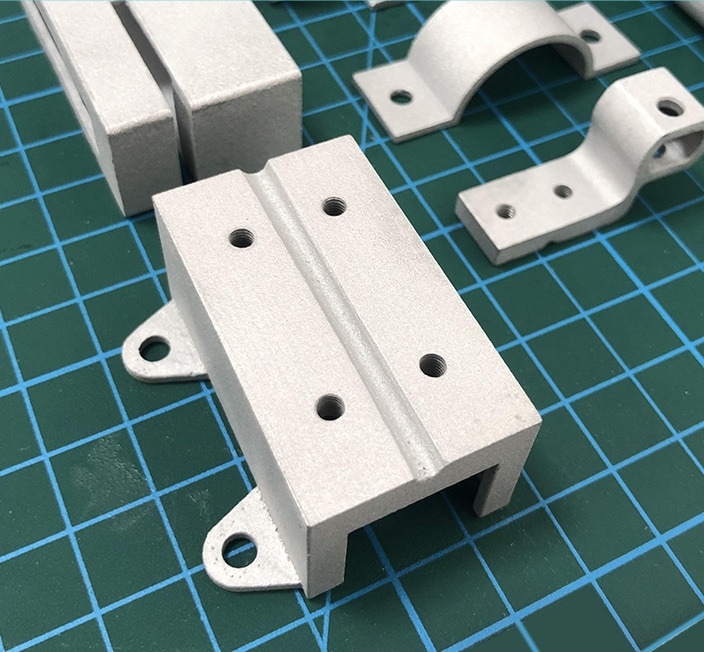

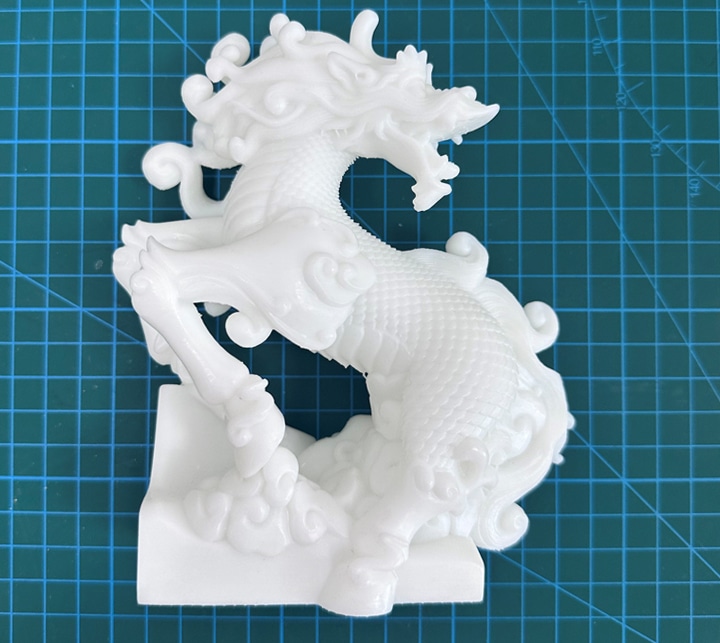

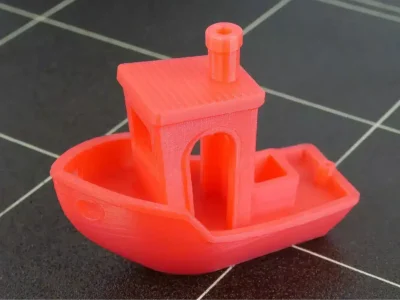

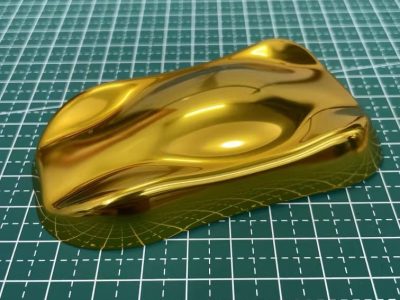

3D printed parts showcase

We serve more than 10,000 customers across various industries such as aerospace, defense, robotics, medical, machinery, automotive, and electronics. Leveraging our rich experience, we are capable of fulfilling a wide range of 3D printing needs, from prototype development to production. This includes visual aids, concept models, injection molding prototypes, form-fit and function prototypes, tooling and casting patterns, jigs, grips, and fixtures, as well as durable production parts.

Available 3D Printing Materials

We offer instant 3D printing quotes for over 25 types of plastics. For metal 3D-printed parts, you can request a quote through our parent company.

SLS

- PA 12

- PA 12 GF

FDM

- PLA/PLA-CF

- PA/PA-CF

- PETG

- ASA

- TPU

- ABS

- PC

- PPS

- PEEK

- ULTEM1010/PEI

- ULTEM9085

HP MJF

- HP PA12

- HP PA 12 GF

SLA

- Standard Resin

- Clear Resin

- Tough Resin 2000

- Durable Resin

- High Temp Resin

- Grey pro Resin

- Flexible Resin

SLM

- ALSi10Mg

- 6061

- 316L

- 17-4PH

- MS1/1.2709

- TC4

We can source any other material on request. Please contact us

Available Post Processing for 3d printing

Post-processing improves both the look and performance of 3D prints, giving them a polished surface, rich colors, or increased strength. It’s especially useful for parts that are visible or need added functionality. However, it might be unnecessary for rough prototypes or internal parts where appearance isn’t essential.

As-machined

Perfect for functional prototypes or internal components where aesthetics aren’t a priority.

Colored

Improves visual appeal and durability with a range of color choices and surface protection options.

Polishing

Minimizes roughness to create a smoother, more visually appealing surface on exposed parts.

Electroplating

Applies a metal coating to enhance strength, wear resistance, and electrical conductivity.

FAQ's about 3d printing service

These 3D printing technologies each have unique features:

- FDM (Fused Deposition Modeling): Uses thermoplastic materials that are melted and extruded layer by layer. It is cost-effective, suitable for rapid prototyping and low to medium strength requirements.

- SLS (Selective Laser Sintering): Uses a laser to sinter powdered material into solid structures. Ideal for complex geometries and functional prototypes, with high material strength.

- SLA (Stereolithography): Uses a laser to cure photopolymer resin, building objects layer by layer. It offers high precision and smooth surfaces, perfect for applications requiring high detail and accuracy.

- MJF (Multi Jet Fusion): Uses jetting technology and heat to fuse powdered material, producing high-strength parts. Suitable for industrial applications with fast production speeds.

3D printing is a manufacturing technology that creates three-dimensional objects by adding material layer by layer. Unlike traditional subtractive manufacturing, 3D printing is an additive process, controlled by computer-aided design (CAD) models. This technology is widely used in prototyping, custom parts, medical devices, and artistic creations.

For budget-conscious and rapid prototype testing, FDM is the best choice. FDM printers are relatively inexpensive, easy to operate, and have low material costs, making them ideal for quickly creating and testing prototypes. Additionally, FDM technology supports a wide range of materials to meet various testing needs.

For high-strength material requirements, SLS and MJF are excellent choices. Both technologies can use high-strength engineering plastics like nylon, producing parts with good mechanical properties and durability. SLS is ideal for complex geometries, while MJF is suitable for batch production and industrial applications.

For achieving the highest precision and surface quality, SLA (Stereolithography) is the top choice. SLA technology uses a laser to cure photopolymer resin, allowing for extremely high printing precision and very fine surface details, making it perfect for applications that demand high accuracy and aesthetics, such as medical models and jewelry design.