Custom CNC Machining Service

Receive an immediate online quote for your metal or plastic CNC machined parts, suitable for everything from rapid prototyping to full production. Select from over 100 materials and 60 surface finishes. We are certified to ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016 standards. Enjoy expedited lead times, with some as quick as one day.

- 35+ surface finishes,80+ metals& plastics

- Fast Lead Time

- Quote for 1-10,000 parts

Our CNC Machining Service Capabilities

Our network of manufacturing partners gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

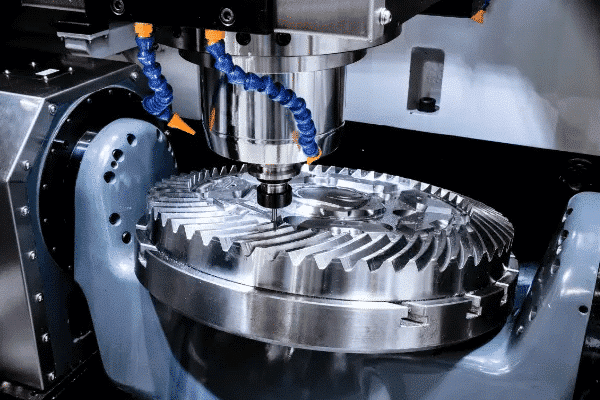

CNC Milling

Access over 1,000 milling centers including standard 3-axis mills,indexed 3+2-axis mills & fully-continuous 5-axis mills

Learn more

CNC Turning

Access over 300 turning centers,including Swiss lathes and multi-axis mill turns.

Learn more

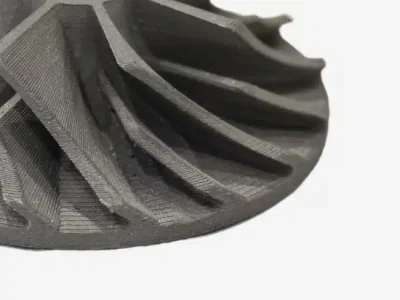

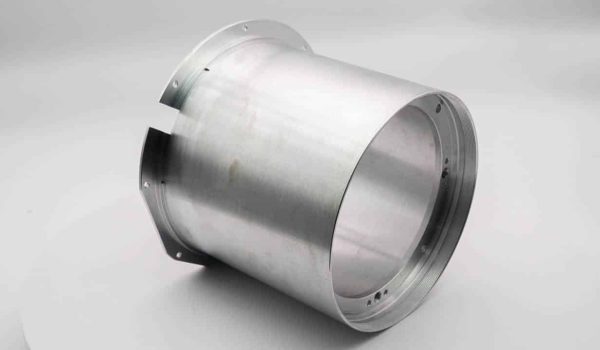

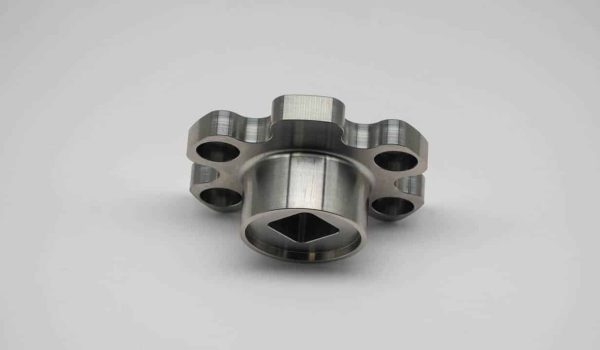

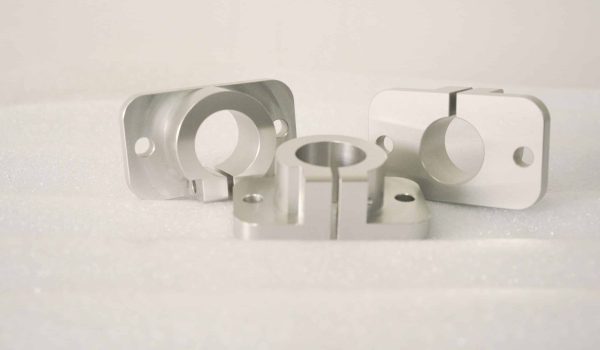

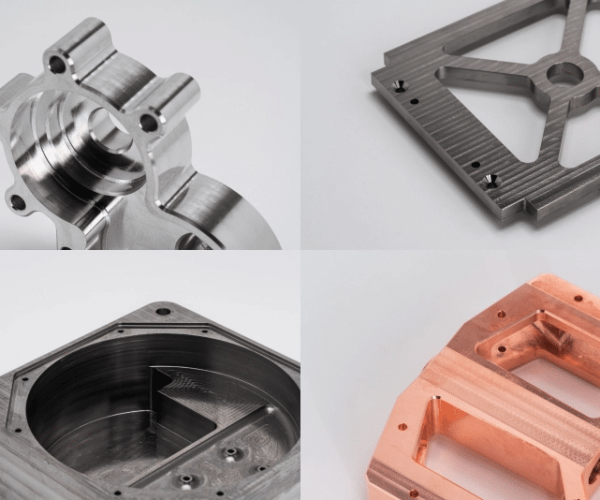

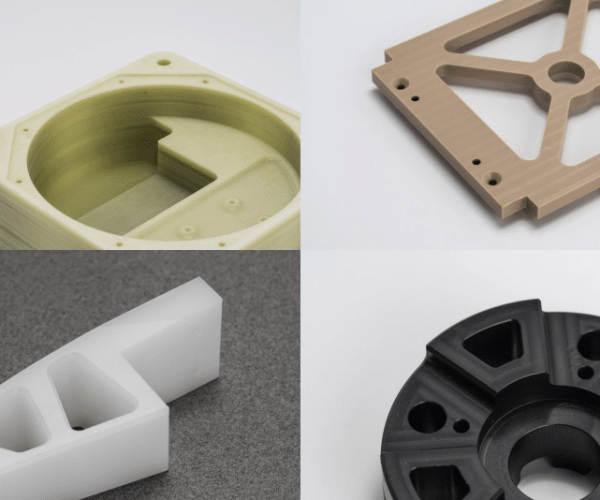

Parts Showcase

We serve over 10,000 customers across industries including aerospace, defense, robotics, medical, machinery, automotive, and electronics.

With years of experience, we handle a wide range of 3D printing needs — from prototypes to production.

Our capabilities cover visual models, concept parts, injection molding samples, functional prototypes, tooling patterns, jigs, grips, fixtures, and even durable end-use parts.

Maximum part size for 3- and 3+2-axis CNC milling

There are several types of CNC milling machines, each with its own distinct maximum part size. 3-axis and 3+2 axis machines have the lowest start-up costs and can produce parts with relatively simple geometries.

|

Size |

Metric units |

Imperial units |

|---|---|---|

|

Max. part size for all materials |

2000 x 1500 x 200 mm |

78.7 x 59.0 x 7.8 in |

|

Min. feature size |

Ø 0.50 mm |

Ø 0.019 in |

Available materials for CNC milling

Metal Material

A wide range of metals for CNC machining, with applications in multiple industries. Ideal for both one-off prototypes and end-use custom parts.

Browse CNC milling metal materials

Plastics

A wide range of plastics for CNC machining, with applications in multiple industries. Ideal for both one-off prototypes and end-use custom parts.

Browse CNC milling plastic materials

Available Finishes for CNC Machining

Attain the ideal finish with our extensive selection of surface treatments. Whether you need anodizing, plating, or painting, we guarantee your parts will fulfill both aesthetic and functional requirements.

Anodizing

Anodizing is an electrochemical process used to enhance the surface of metals, primarily aluminum, improving its corrosion resistance, wear resistance, and providing a variety of decorative colors.

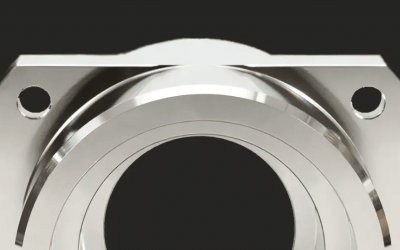

Polishing

Polishing is a finishing process that enhances the surface finish and appearance of materials by removing imperfections and producing a high luster.

Sand Blasting

Sand blasting is a surface treatment process that involves propelling abrasive particles under high pressure against a surface to clean it or modify its texture.

Tumbling

Tumbling is a finishing technique where parts are placed in a rotating barrel with abrasive media to smooth and polish the surfaces through friction and impact.

Electropolish

Electropolishing is a metal finishing process that uses an electrochemical solution to remove microscopic layers of material from a workpiece, enhancing its surface smoothness and shine.

Heat Treatment

Heat treatment is a controlled process used to alter the physical and sometimes chemical properties of a material, typically metal, to achieve desired mechanical properties such as hardness, ductility, and strength.

Brushed Finish

A brushed finish is achieved by polishing a metal surface with a fine bristle brush on a belt or wheel that creates a consistent, unidirectional satin-like texture.

Black Oxidize

Black oxidizing is a chemical conversion coating process used on metals, primarily steel, to produce a black surface layer that offers mild corrosion resistance and reduces light reflection.

Powder Coating

Powder coating is a finishing process where a dry powder paint is electrostatically charged and sprayed onto a surface, then cured under heat to form a hard, durable, and colorful protective layer.

FAQ's about CNC machining

The cost of your CNC machining project depends on some factors such as the design, tolerance require, material, machining times, and human resources that have to be input into the project. You can send us your CAD file so we can prepare the quote for you.

- Select The Right Machining Process: One of the best techniques to reduce the cost f CNC machining is to choose an efficient machining process. Generally, you need a professional machining company that will guide you through the complete CNC machining cost-reduction process.

- Refine The Design of The Part: If you have a perfect design for the CNC machining part, it can significantly reduce machining costs.

- Right Tooling Reduces The Cost: Generally, traditional machining centers have manual tooling which increases the cost of the metal part. Find the best CNC machining company near you with the latest CNC machining equipment.

We can accommodate the prototyping and production of large machined parts, plastic or metal. Our maximum CNC machining build envelope is 2000 mm x 1500 mm x 300 mm — suitable even for large-scale furniture and architectural components.

Yes, we provide 5 Axis CNC machining solutions for metal parts with complex geometry and high precision standards. We offer our services for a range of materials with precise tolerances, curved surfaces, and fine detailing. Additionally, we provide post-processing services like plating, powder coating, and anodizing.

Down to 0.001mm.

CNC (Computer Numerical Control) machining is a manufacturing process where computer programming automatically controls machine tools. It allows for precise cutting, milling, turning, and drilling operations on various materials, such as metals, plastics, and wood. CNC machining is widely used for everything from small-scale prototyping to large-scale production.

CNC stands for “Computer Numerical Control.” This means that machines are automatically controlled through predefined computer instructions, ensuring precision and consistency in the machining process.

You can start learning CNC machining through these steps:

- Enroll in Vocational Training or Technical Schools: Many technical schools offer training programs for CNC machining.

- Online Courses: Numerous platforms offer online courses in CNC programming and operations.

- Hands-on Experience: Gaining practical experience by operating CNC machines in a factory setting or through internships is crucial.

- Self-Study: Learn G-code and CAD/CAM software through books, video tutorials, and online forums.

To enter the CNC machining field, you can follow these pathways:

- Get Relevant Education and Training: Attending a technical school or a vocational program is a common entry point.

- Obtain Certifications: Some organizations offer certifications for CNC operators or programmers, which can boost your job prospects.

- Internships or Apprenticeships: Gaining work experience through internships or apprenticeships in machine shops is highly beneficial.

- Learn Programming Skills: Mastering CAD/CAM software and G-code programming is essential for becoming a CNC operator.